Steam Drum Level, 3 Element Control

Setelah puas bicara masalah Photography dan Travelling, kita beralih ke pembahasan Power Plant Technology. Kali ini bahasanya saya sajikan in English aja yah, biar bisa di baca sama orang-orang bule. 🙂

In my previous post “Where does the Steam come from?” we’ve understood that water is pumped from feedwater tank via boiler economizer to steam drum. Water is introduced to steam drum through perforated pipe from the bottom of steam drum along the length of the drum, and maintained to fill up a half volume of the drum.

The purpose of steam drum in boiler is to separate water and steam in water/steam natural circulation, where the saturated steam that separated from water/steam mixture will passes from steam drum then will be superheated in the superheater and finally convert to superheated steam as a final product of boiler. On the otherside the water will be circulated through heat transfer media via furnace wall tubes then flowing back to the steam drum as water/steam mixture that will continuously separated from saturated steam.

In steam drum, there is a phenomenon called “shrink and swell effect”. In case of boiler load increasing (steam flow), it will increase steam bubble volume, then steam drum will decreased and fuel firing (heat input) will increase. At this moment, drum level will indicate high, this is what we called swell effect. When drum level is indicated high, feed water will reduce the flow in response of drum level high. This is an appropriate control response, it should increase feed water flow during high load!! The result, boiler will be trip because of drum level alarm low.

In other case, due to a decrease in load (steam flow), it will decrease (shrinkage) in drum level due to a decrease in steam-bubble volume. Resulting increase in drum pressure and a decrease in heat input. Feed water flow response to this shrink effect with increasing feed water flow, then there will water carry over that can damage boiler tubes and turbine.

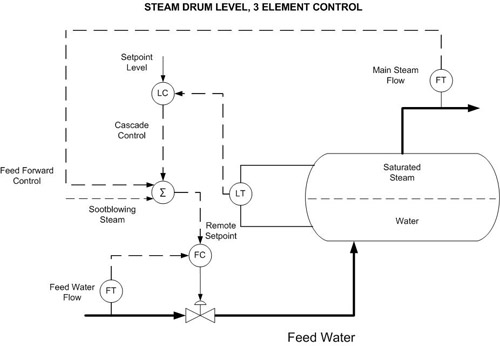

This process phenomenon can be overcome with more sophisticated control strategy, that called steam drum three element control. The three element control refer to three process variable in steam drum control:

1. Feed water flow

2. Drum level

3. Main Steam flow

The purpose of 3 element control strategy is not only maintaining mass balance of water input and steam output in steam drum but also to achieve boiler safety operation in “shrink and swell effect”. Configuration of this control strategy employs cascade control of drum level control (master) and feedwater flow control (slave), then configuring feedforward control, where total steam flow (main steam flow, sootblowing steam, etc) will be corrected by drum level control output as remote setpoint for slave. This configuration will result mass balance between feedwater and total steam flow, and also become a smooth control in shrink and swell condition.

In the next post, we will discuss about how to calculate differential pressure of steam drum as level indication.

kejam lu pan

pake bahasa indonesialah

katanya orang indon

ono versi boso jawa-ne gak iki ? 😀

@ bapake dina: tolong ditranslate ke boso jowo nggih. 🙂

oia modellingnya gmna mas..?? klo waktu kape saya juga berkutat yg 3 element itu.. dimana didasarkan pada 3 element. pressure,Flow, dan Level.. dmna levelnya sbgai master controlnya….

Kalo untuk simple modelling, yang pertama kali dilakukan adalah mengidentifikasi sistem, menentukan variable input dan output. Menurut saya untuk modelling yang realistis untuk steam drum, kita harus memperhatikan bahwa water dan steam density bervariasi tergantung dari pressure, yang mana pressure sendiri tergantung dari heat input dan juga feedwater tempearure, demikian juga dengan feedwater flow dan main steam flow. Terus terang saya juga belum pernah bikin modellingnya. Kalo mas pernah bikin pas KP, mungkin bisa dishare ke saya? karena menarik juga variable prosessnya pakai pressure, cz saya belum pernah ketemu yang pake pressure.

om topan ikut modelling juga kah? no agensinya brp? boleh dicontact bwt hunting neh,wkwkwkwkk…

**o’on mode : on

Walah, bapake dina sekarang dah cari2 model tho, mau model co ato ce? saya bisa sediakan. hehe

**o’on mode juga ah..

haha..

btw,3element pake variable pressure to?

mas, saya sedang mengerjakan tugas akhir yang menyangkut drum level control dan steam drum dalam bentuk simulasi…..kalau ada materi yang bersangkutan bisa saya minta??karena saya ingin cepat menyelesaikan tugas akhir saya secepatnya…..terima kasih…

gmana mas sdh dapatpeodelan matematisnya blum

Apik tenan, singh tak waco tak copy yo mas…

pemodelan sistem dinamiknya seperti apa ya? kalau dipasang secara horizontal, fungsi level terhadap volumenya seperti apa?

terimakasih

Mantap mas penjelasan tentang shrink dan swell effect di steam drum..

Salam,

M. Taufik

mas topan,

saya mau tanya nih

kalo menghitung volume steam drum pada boiler (water tube) gimana cara nya???

misalkan di ingin mencapai tekanan 2 bar, trus volume air dan temperatur nya yang optimal berapa y???

terimakasih atas artikel nya

jika anda tdak kbratan tLg di kirim jawabannya ke email saya

mgs.abdussalam@yahoo.com

jawaban saudara akan sangat membantu

terimakasih